HVAC Disassembly and Cleaning

The design of the cup holder on the 1999½ Audi A4 (and other years/models) has a rather problematic side effect. If and when (and it will happen) a drink spills, it drips all over your radio and HVAC causing the keys to being sluggish and sometimes stick. While in +20°C weather the key will probably return fairly quickly, at -35°C your lucky if the key returns at all.

Something needed to be done:

This procedure will deal with the HVAC unit itself. The radio (Concert) is much easier to disassemble and won't be covered here.

Dealer replacement value of the unit (8D0 820 043N B98) is over 800 $CDN (500 $US). Treat it with care. You've got better things to spend that money on if you happen to damage it. That being said, I take no responsibility of your actions in removing and opening your unit. These were the steps I did in order to back out of Audi's design oversight. My vehicle is still under warranty, I probably should have got it replaced at Audi's expense. However, I don't feel to comfortable with my dealer ripping apart my center console.

Your unit may differ, but I suspect the same technique will still apply.

jonese@zener.comUNIT REMOVAL HINTS

Here

is the center console with the radio

and HVAC unit removed.

How you get to this step will probably be the most unprofessional work you'll

ever perform on your car. I have no idea what Audi was thinking when they

decided on the mounting method for the unit (or I'm missing something here?).

Here

is the center console with the radio

and HVAC unit removed.

How you get to this step will probably be the most unprofessional work you'll

ever perform on your car. I have no idea what Audi was thinking when they

decided on the mounting method for the unit (or I'm missing something here?).

The radio was a breeze. Make sure you know it's unique

security code before removing it. The difficult part is getting the

proper key removal tools. If your Audi/VW dealer is reasonable, they may

be willing to release the radio for you if you take a visit to them. Once

you've got the radio released from it's mounting clips, it's a simple matter of

pulling it out.

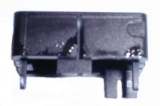

The HVAC unit is held in place with FOUR angle brackets that clip into place

when it was initially installed at the factory. These are troublesome to

release. The top pair are easy to release with a small screwdriver.

You can pull them slightly forward from their normal position so they no longer

catch the surrounding plastic. The bottom clips are about the same

distance apart, but are quite a bit further back along the bottom side. I wasn't able to see

them from the outside. I had to jamb two thick screwdrivers under the

unit distorting the plastic brace above the ash tray. The idea was to

push the brace away from the clips so you could pull the unit out without them

catching.

In stead of pulling, I found that putting your hand inside the radio opening and

pushing the unit out was easier. It's your choice, but there isn't much of

a grip on the front of the unit for you to pull on.

During

your extraction, be

careful not to damage the bottom rubber bushings as you deal with the bottom

retainer-clips. These are for shock suppression and probably reduce the rattling of assemblies..

During

your extraction, be

careful not to damage the bottom rubber bushings as you deal with the bottom

retainer-clips. These are for shock suppression and probably reduce the rattling of assemblies..

This

is the dreaded bottom retainer-clip that holds the bottom of the unit in. Due to the difficulty in removing the unit with these clips

installed, I have

removed them before re-installing. This will make removal MUCH easier should you

need to remove it again in the future. I have no idea as to what impact this

will have on holding the unit flush with the center instrument trim. Everything seems

fine at the moment.

This

is the dreaded bottom retainer-clip that holds the bottom of the unit in. Due to the difficulty in removing the unit with these clips

installed, I have

removed them before re-installing. This will make removal MUCH easier should you

need to remove it again in the future. I have no idea as to what impact this

will have on holding the unit flush with the center instrument trim. Everything seems

fine at the moment.

TOOLS

![]() Nothing

really special except for a really-really small Torx screwdriver. My Torx

set didn't go small enough. I found that one of my jeweler's flathead

screwdriver's fit just in side the Torx head without slipping.

Nothing

really special except for a really-really small Torx screwdriver. My Torx

set didn't go small enough. I found that one of my jeweler's flathead

screwdriver's fit just in side the Torx head without slipping.

DISPLAY-HEAD SEPARATION

Here's

the unit removed from the center console.

Here's

the unit removed from the center console.

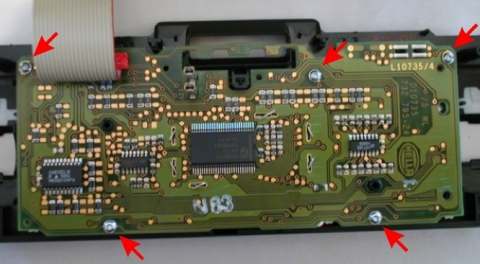

Set

the unit face down on some soft clean surface being careful not to scratch the

face. You'll

need to remove the FOUR screws on the backside of the assembly (Torx head).

These are relatively short and easy to remove.

Set

the unit face down on some soft clean surface being careful not to scratch the

face. You'll

need to remove the FOUR screws on the backside of the assembly (Torx head).

These are relatively short and easy to remove.

You may

choose to remove the temperature blower (Torx head), but on this style of unit

it wasn't necessary. Your unit may differ. I removed the TWO screws and

pulled up. The contacts for the motor just slide out like a connector.

You may

choose to remove the temperature blower (Torx head), but on this style of unit

it wasn't necessary. Your unit may differ. I removed the TWO screws and

pulled up. The contacts for the motor just slide out like a connector.

At

this point, the display-head will be lose, but still inseparable. There are TWO hooks

on the top, near where the temperature blower is that

need to be slightly depressed.

At

this point, the display-head will be lose, but still inseparable. There are TWO hooks

on the top, near where the temperature blower is that

need to be slightly depressed.

Slip

the end of the jeweler's screwdriver tip between the display-head and the unit-body.

Gently lift the unit-body plastic up over the display-head. Go easy! If you look

closely, you can see dents from my initial attempts. You'll

now have the display-head section separated from the unit-body by way of a

ribbon cable. ESD precautions.

Slip

the end of the jeweler's screwdriver tip between the display-head and the unit-body.

Gently lift the unit-body plastic up over the display-head. Go easy! If you look

closely, you can see dents from my initial attempts. You'll

now have the display-head section separated from the unit-body by way of a

ribbon cable. ESD precautions.

You now have exposed a good portion of the unit electronics. This is static sensitive device. Handle as little of the electronic components as possible. Don't be walking around your house with the unit open to show all your friends how cool it looks inside. Even the tiniest of electrostatic discharge can destroy the unit. If you live in a low humidity area, you might also want to think about grounding your self.

Carefully

place the display-head face down. Remove the FIVE screws that hold the

faceplate to the display board.

Carefully

place the display-head face down. Remove the FIVE screws that hold the

faceplate to the display board.

Set

aside the electronics portion for later reassembly. You might want to make

sure the LCD display is clean. Don't use any chemicals that may damage the

glass.

Set

aside the electronics portion for later reassembly. You might want to make

sure the LCD display is clean. Don't use any chemicals that may damage the

glass.

KEY REMOVAL

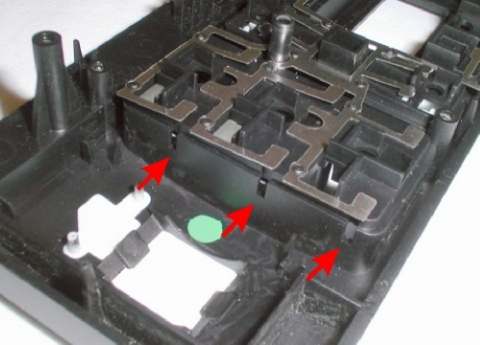

Place

the keypad assembly face down. You'll notice that the keys get some of their

bounce from the metal frame that floats around the backside of the keys.

One must be careful not to stress and damage the frame

when removing keys.

Place

the keypad assembly face down. You'll notice that the keys get some of their

bounce from the metal frame that floats around the backside of the keys.

One must be careful not to stress and damage the frame

when removing keys.

Locate

the slider-holes for each of the keys that you wish to remove. Each key has at

least TWO holes that guide the key. The holes also function to

limit the keys travel (to retain the key in the cavity). In the

factory, these keys are pushed in from the front past the point of the interference

inside the slider-holes.

You're going to have to reverse that process in order to remove the key. It's not easy! The

assembly wasn't designed with key removal in mind.

Locate

the slider-holes for each of the keys that you wish to remove. Each key has at

least TWO holes that guide the key. The holes also function to

limit the keys travel (to retain the key in the cavity). In the

factory, these keys are pushed in from the front past the point of the interference

inside the slider-holes.

You're going to have to reverse that process in order to remove the key. It's not easy! The

assembly wasn't designed with key removal in mind.

To

remove a key, you need to push the key past it's interference point. Do one side

of the key,

then the other. Great care must be taken NOT to damage

the cavity glide paths and key latches or the key will no longer travel smoothly

or 'pops- out' when you take your finger off. TAKE YOUR TIME!. If a

key isn't releasing, find out why. It takes a bit of pressure, but not a whole

lot. After 2 or 3 keys, you should get a good feel as a technique.

To

remove a key, you need to push the key past it's interference point. Do one side

of the key,

then the other. Great care must be taken NOT to damage

the cavity glide paths and key latches or the key will no longer travel smoothly

or 'pops- out' when you take your finger off. TAKE YOUR TIME!. If a

key isn't releasing, find out why. It takes a bit of pressure, but not a whole

lot. After 2 or 3 keys, you should get a good feel as a technique.

The two rocker keys (TEMPERATURE & FAN SPEED) can be easily removed by pressing

down simultaneously on the studs located on the back of the key. (The studs are

the plastic portion that are in contact the switches on the display board).

Once

again, be

careful not to damage the guides. Here you can see some minor damage I had. You

should clean out any plastic bits that were created when the key popped out. Don't get too

carried away or you'll risk the key not holding when you reassembly everything.

Once

again, be

careful not to damage the guides. Here you can see some minor damage I had. You

should clean out any plastic bits that were created when the key popped out. Don't get too

carried away or you'll risk the key not holding when you reassembly everything.

CLEANING

Now

you have all the necessary keys removed from their respective cavities (take

note before you start as to which keys are sticky!). Examine each key and

cavity for the source of the problem. Dirt and fluid reside are prime

candidates.

Now

you have all the necessary keys removed from their respective cavities (take

note before you start as to which keys are sticky!). Examine each key and

cavity for the source of the problem. Dirt and fluid reside are prime

candidates.

Notice

the shinny "goop". This is causing the keys to stick to the keypad assembly.

Yours may look different, but this is what Coke leaves behind on my keys.

Notice

the shinny "goop". This is causing the keys to stick to the keypad assembly.

Yours may look different, but this is what Coke leaves behind on my keys.

Clean

the keys with a suitable cleaner. I used Simple Green. Don't use anything

too strong (like rubbing alcohol), or you'll damage the plastic. I also washed

the parts under warm soapy water to remove any residue. Make sure all the parts

are free of water or rust will develop on the metal spring frame.

Clean

the keys with a suitable cleaner. I used Simple Green. Don't use anything

too strong (like rubbing alcohol), or you'll damage the plastic. I also washed

the parts under warm soapy water to remove any residue. Make sure all the parts

are free of water or rust will develop on the metal spring frame.

REASSEMBLY

Reassembly is just the reversal of the above steps. Take your time, double check to put the keys back in the correct cavities. Make sure you're orienting the keys correctly (e.g.. No up-side-down TEMPERATURE or FAN SPEED keys!). Double check that each key sits smartly into each cavity without binding. If the key tends to pop out, you may have damaged the cavity guides or hooks during the removal process. I didn't run into this, but you can try fiddling with the plastic guides or hooks to bring them out a little so there is a interference fit.

When your all done, sit back and admire the crisp clean "click" when you press the buttons.

jonese@zener.com

Good luck!

Last updated: 2002/08/08 21:11